Short Lead Time for Fish Oil Mixing Tank - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang

Short Lead Time for Fish Oil Mixing Tank - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power(kw) |

||

|

L |

W |

H |

||

|

SJRQ-Ø219*3000 |

3000 |

380 |

640 |

0.25 |

|

SJRQ-Ø219*4000 |

4000 |

380 |

640 |

0.25 |

working principle

The protein water extruded from the Screw Press must be preheated before entering the Tricanter, and the temperature can be controlled at 90℃~95℃, which is conducive to the separation of oil and water. The working principle of Protein Water Heater is to heat protein water by indirect heat exchange between steam and protein water. The steam enters the shell insulation cover from the steam inlet of the power end, and the protein water enters the main shaft of Protein Water Heater from the non-power end. After indirect heat exchange between steam and protein water, the condensate water generated in the heat exchange process is discharged from the condensate outlet at the bottom of the non-power end, and the heated protein water is discharged from the outlet at the power end and then fed into the Tricanter for centrifugal separation. Steam and protein water enter the Protein Water Heater from opposite directions in order to achieve better heating effect, so that the temperature of the protein water discharged from the outlet is the highest.

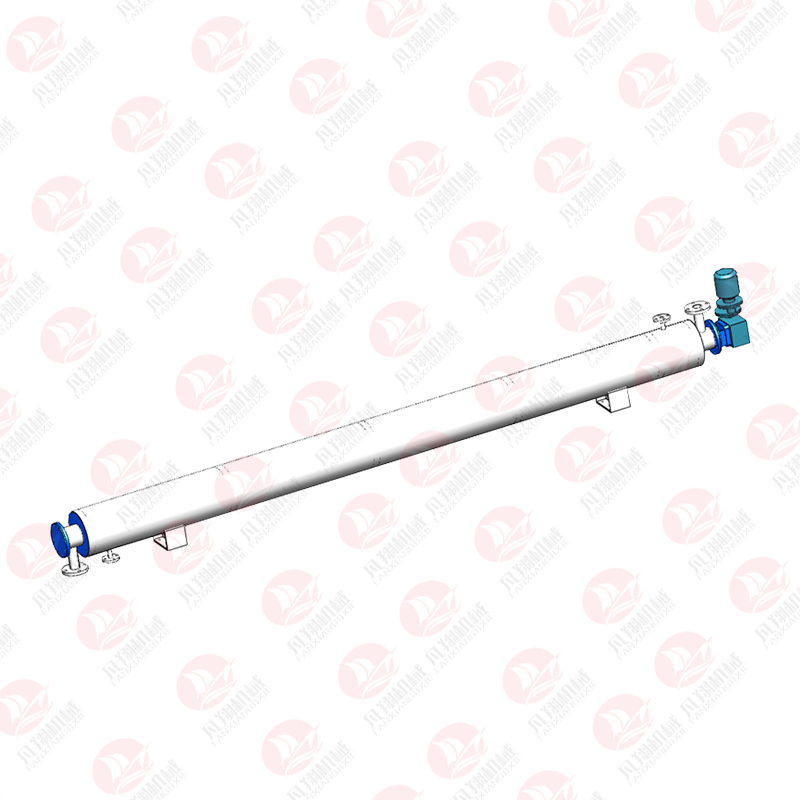

Structure

|

No. |

Description |

No. |

Description |

|

1. |

Protein water inlet flange |

5. |

Spindle joint |

|

2. |

Condensed water outlet flange |

6. |

Steam inlet flange |

|

3. |

Foot stand |

7. |

Protein water outlet flange |

|

4. |

Barrel-body parts |

8. |

Insulation cover |

Installation collection

Product detail pictures:

Related Product Guide:

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Short Lead Time for Fish Oil Mixing Tank - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang , The product will supply to all over the world, such as: Swiss, Tanzania, Bandung, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!