Original Factory Hammer Grinder Machine - Drier (High Quality Fish Meal Coil Pipe Drier) – Fanxiang

Original Factory Hammer Grinder Machine - Drier (High Quality Fish Meal Coil Pipe Drier) – Fanxiang Detail:

|

Model |

Heating Surface Area (m2) |

Dimensions(mm) |

Power (kw) |

||

|

L |

W |

H |

|||

|

SG-Ø1300*7800 |

88 |

11015 |

2600 |

2855 |

37 |

|

SG-Ø1600*7800 |

140 |

10120 |

2600 |

3105 |

45 |

|

SG-Ø1600*8700 |

158 |

11020 |

2600 |

3105 |

55 |

|

SG-Ø1850*10000 |

230 |

12326 |

3000 |

3425 |

75 |

|

SG-Ø2250*11000 |

370 |

13913 |

3353 |

3882 |

90 |

working principle

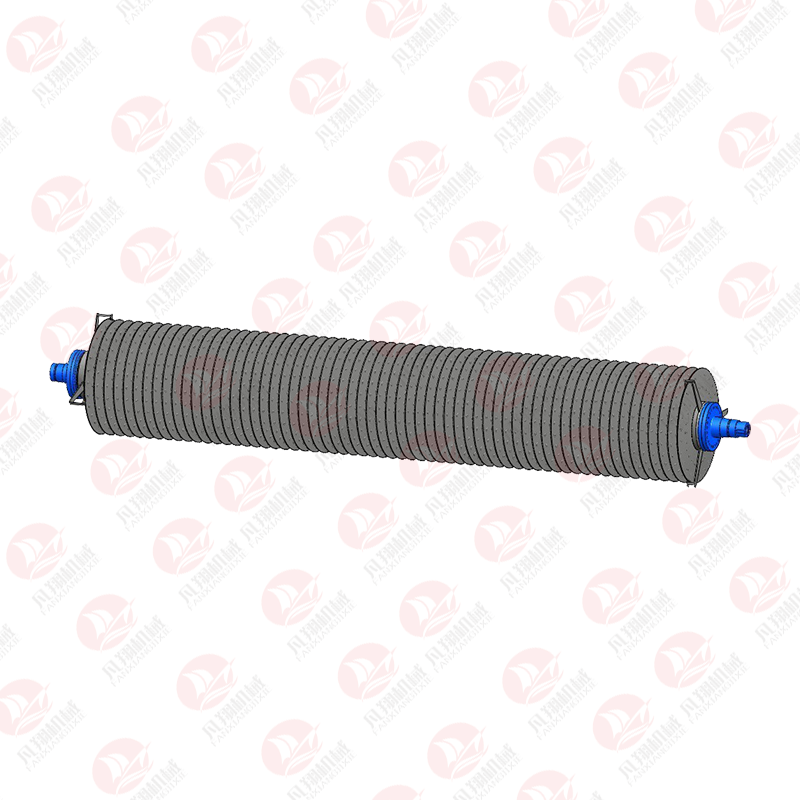

The Drier is composed of a rotating shaft with steam heating and a horizontal shell with steam condensate water. In order to improve the drying speed, the shell adopts a sandwich structure, and the condensate water generated by the steam heating of the rotating shaft (generally between 120℃ and 130℃) has a certain heating effect on the fish meal inside the cylinder.

The shaft is welded with heating coils, and the coil is fitted with angle adjustable wheel blades. It can not only heat the fish meal, but also move the fish meal along the direction of the end. The steam distribution device inside the rotating shaft can make the steam evenly distributed to each heating coil. The steam and condensate water flow in the coils on both sides of the coils respectively, so that the heating coils maintains a constant high temperature.

With the rotation of the shaft, the fish meal is fully stirred and mixed under the joint action of the wheel blades and the coils, so that the fish meal has the maximum contact with the rotating shaft and the surface of the coils. The top of the Drier is equipped with a inducting box for collecting waste vapor and preventing the fish meal from being sucked into the ducting pipeline. The closed window cover is used to avoid the inhalation of cold air. The steam enters from the shaft end of the feed port, and the condensate water is discharged from the shaft end of the fishmeal outlet into the jacket, and then discharged from the jacket of the other shaft end, finally converges into the total condensate water pipe.

Installation collection

Product detail pictures:

Related Product Guide:

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We've been striving to be an excellent business enterprise partner of you for Original Factory Hammer Grinder Machine - Drier (High Quality Fish Meal Coil Pipe Drier) – Fanxiang , The product will supply to all over the world, such as: kazan, South Africa, Colombia, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!