Effective odour reduction in fish meal plants demands advanced solutions. Operators rely on Waste Vapor Treating Equipment For Fish Meal Plant to maintain air quality and satisfy regulatory demands. Proactive odour control boosts operational performance. It also protects community relations and safeguards the reputation of the facility.

Key Takeaways

- Rapid processing of raw fish combined with advanced waste vapour treatment systems greatly reduces odour emissions and improves plant performance.

- Regular equipment maintenance and strict process control prevent odour problems and ensure consistent air quality compliance.

- Open communication and active engagement with the local community build trust and help minimise odour complaints.

Main Sources of Odorous Waste Vapours

Raw Material Reception and Storage

Raw fish begins to decompose quickly after harvesting. When operators store raw material for extended periods, microbial activity increases. This process releases volatile compounds such as ammonia and hydrogen sulphide. These gases create strong, unpleasant odours. Proper temperature control and rapid processing reduce the risk of odour formation at this stage.

Cooking and Pressing Processes

Cooking and pressing represent critical points for odour generation. During cooking, operators heat raw material to temperatures typically between 95°C and 100°C. This step coagulates proteins and liberates oil, but overcooking can increase suspended particles in stickwater, making evaporation more difficult and raising odour emissions. Pressing separates liquids from solids, and its efficiency depends on several operational metrics.

| Process Operation | Performance Metric | Effect on Odorous Waste Vapours |

|---|---|---|

| Cooking | Temperature control | Overcooking increases odour emissions |

| Cooking | Heating time and heat load | Influences odour generation |

| Pressing | Screw speed, tightness, and maintenance | Impacts liquid removal and odour release |

Operators who monitor these metrics closely can minimise odour release during processing.

Drying and Cooling Stages

The drying stage removes moisture from the pressed fish cake. High temperatures and airflow volatilise residual organic compounds, which escape as odorous vapours. Cooling the dried meal can also release lingering smells, especially if airflow systems lack proper filtration.

Wastewater and By-product Handling

Handling stickwater, press liquor, and other by-products presents another major odour source. Inadequate containment or delayed treatment allows organic matter to break down, releasing malodorous gases. Efficient wastewater management and prompt by-product processing help control emissions at this stage.

Waste Vapor Treating Equipment For Fish Meal Plant

Advanced Condensation and Scrubbing Systems

Operators in modern fish meal plants rely on advanced condensation and scrubbing systems to capture and neutralise odorous vapours. These systems cool and condense steam and volatile organic compounds, reducing their release into the atmosphere. Chemical scrubbing towers, when stabilised with agents such as hydrogen peroxide and sodium silicate, can achieve hydrogen sulphide removal efficiencies up to 98%. A pilot-scale study in a wastewater treatment plant confirmed these high removal rates, highlighting the importance of optimised operating conditions for maximum odour control. Analytical methods, including gas chromatography and olfactometry, allow precise measurement of odour compound reductions, ensuring that Waste Vapor Treating Equipment For Fish Meal Plant meets strict environmental standards. Operators benefit from quantitative data on reactant consumption and process economics, which supports informed decision-making.

Use of Biofilters and Chemical Scrubbers

Biofilters and chemical scrubbers play a vital role in reducing odour intensity in fish meal processing. Biofilters use microbial consortia to degrade volatile nitrogenous compounds, such as trimethylamine and ammonia, which are responsible for strong odours. Experimental data show that biotrickling filters can remove up to 92% of trimethylamine and 99.8% of ammonia, with high elimination capacities. Ammonia-oxidising bacteria sustain this removal, ensuring consistent performance. Chemical scrubbers complement biofilters by adsorbing and chemically reacting with remaining odorous compounds. Together, these technologies form an essential part of Waste Vapor Treating Equipment For Fish Meal Plant, delivering robust and reliable odour reduction.

High Efficiency Separation and Vapour Collection

High efficiency separation and vapour collection systems ensure that odorous compounds do not escape into the environment. These systems use cyclones, demisters, and multi-stage separators to capture fine droplets and particulates from process vapours. Operators install these components at key emission points, such as dryers and cookers, to intercept odorous streams before they reach the atmosphere. Waste Vapor Treating Equipment For Fish Meal Plant with advanced separation technology reduces the load on downstream treatment units, improving overall plant efficiency. Regular maintenance and monitoring of these systems guarantee sustained performance and compliance with air quality regulations.

Tip: Regular inspection of separation and collection equipment prevents blockages and maintains optimal odour control.

Waste Heat Recovery and Energy Efficiency

Waste heat recovery systems enhance the energy efficiency of fish meal plants while supporting odour reduction. These systems capture residual heat from process vapours and reuse it for preheating raw materials or generating steam. By lowering the temperature of exhaust gases, operators reduce the volatility of odorous compounds, making them easier to treat. Integrating waste heat recovery into Waste Vapor Treating Equipment For Fish Meal Plant not only cuts energy costs but also minimises the environmental footprint of operations. Plants that adopt these solutions demonstrate a commitment to sustainability and regulatory compliance.

Operators who invest in comprehensive Waste Vapor Treating Equipment For Fish Meal Plant benefit from improved air quality, reduced complaints, and enhanced community relations. The combination of advanced condensation, scrubbing, biofiltration, high efficiency separation, and energy recovery forms a robust defence against odour emissions.

Optimising Process Control and Raw Material Handling

Process Automation and Monitoring

Modern fish meal plants achieve superior odour control through process automation and continuous monitoring. Automated systems equipped with advanced sensors track critical parameters such as temperature, humidity, and volatile compound concentrations. These technologies enable operators to detect odour changes early and adjust processing conditions in real time. For example, electronic nose systems have demonstrated the ability to identify shifts in odour patterns, allowing for prompt intervention before spoilage escalates. In aquaculture, integrated sensor networks maintain optimal environmental conditions, which translates effectively to odour management in fish meal production. Automation ensures consistent quality, reduces human error, and supports regulatory compliance.

Timely Raw Material Processing

Rapid processing of raw fish remains essential for minimising odour generation. Operators who implement fast and precise heating achieve better protein coagulation and reduce the retention time at elevated temperatures. This approach limits the release of volatile compounds and lowers the biochemical oxygen demand (BOD) in wastewater, both of which contribute to odour. Upgraded heating systems also facilitate thorough cleaning and complete pasteurisation, improving hygiene throughout the plant. Centrifugal separation and evaporation further enhance product quality and reduce environmental impact. Plants that optimise these steps consistently report lower odour emissions and improved operational efficiency.

Minimising Storage Time

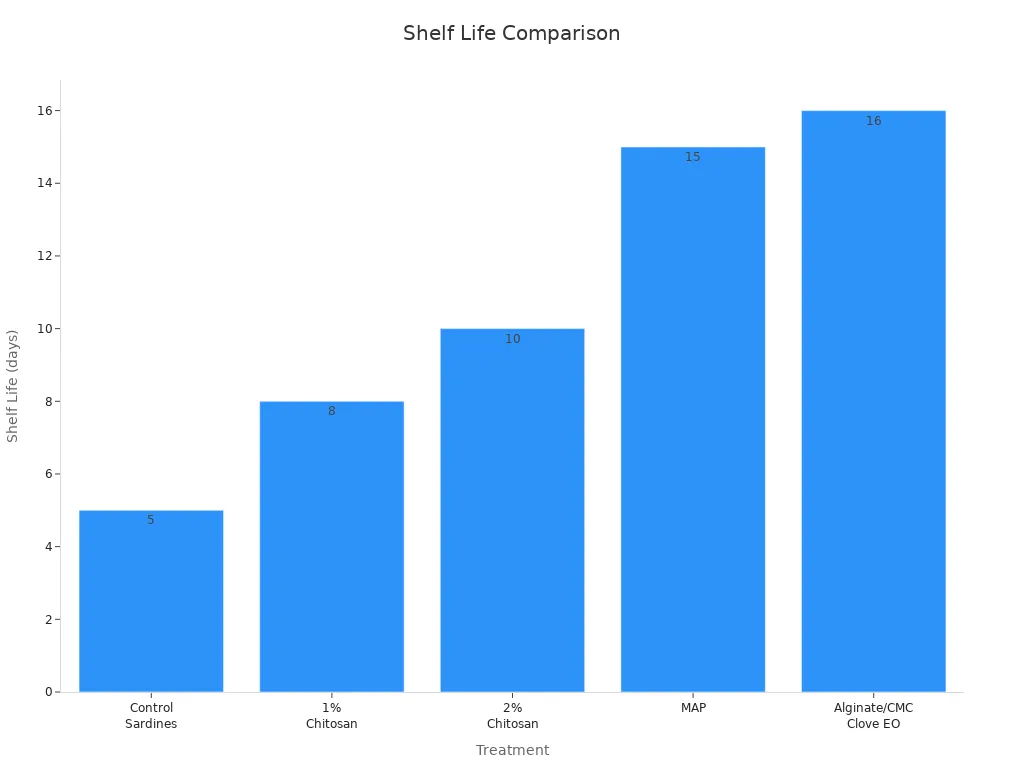

Reducing the storage time of raw materials directly impacts odour control. Data show that shorter storage periods delay spoilage indicators such as total volatile basic nitrogen (TVB-N) and trimethylamine (TMA), while also suppressing microbial growth. The following table summarises the effects of various preservation treatments on shelf life and odour development:

| Treatment / Condition | Shelf Life (days) | TVB-N Acceptability Limit (mg N/100g) | TMA Acceptability Limit (mg N/100g) | Sensory Shelf Life (days) | Microbial Counts / Effects |

|---|---|---|---|---|---|

| Control sardines | 5 | Exceeded on day 13 | Exceeded on day 11-12 | ~11 | Higher microbial growth |

| 1% Chitosan treated | 8 | Exceeded on day 20 | Exceeded on day 19-20 | 18 | Reduced microbial growth |

| 2% Chitosan treated | 10 | Did not exceed by day 20 | >20 days | 19-20 | Lowest microbial growth |

| Oregano EO treated | N/A | Exceeded on day 15-16 | Exceeded on day 14-15 | 16 | Reduced microbial growth |

| Alginate + Resveratrol | N/A | Significantly lower than control | Significantly lower than control | Extended | Marked reduction in TVC, etc. |

| Sodium Alginate + 6-Gingerol | N/A | Retarded fat oxidation and protein breakdown | N/A | Maintained overall quality | Retarded microbial growth |

| Alginate/CMC + 1.5% Clove EO | 16 days | N/A | N/A | Most acceptable attributes | Reduced E. coli O157:H7 |

| Modified Atmosphere Packaging | 15 days (odour onset) | N/A | N/A | Better than vacuum packaging | Reduced bacterial growth |

| O2 Absorber + Oregano EO | 60+ days | N/A | N/A | Sensory shelf life extended | TVC remained below limit |

Tip: Processing fish rapidly, as recommended by FAO guidelines, prevents odour development and maintains product quality. Limiting storage time remains one of the most effective strategies for odour control in fish meal operations.

Practical Tips for Ongoing Odour Management

Staff Training and Awareness

Plant operators achieve consistent odour control when staff understand the sources and impacts of odorous emissions. Regular training sessions equip employees with the skills to identify potential issues early. Operators encourage staff to follow best practices, such as prompt raw material handling and routine equipment checks. Training programmes that include real-life scenarios and clear protocols help staff respond quickly to unexpected odour events. When employees feel responsible for environmental performance, the plant maintains higher standards and reduces the risk of regulatory breaches.

Continuous Odour Monitoring

Continuous odour monitoring provides real-time data on plant emissions. Operators use electronic noses (e-noses) and air quality sensors to track odour events. The following table summarises key measurable parameters and their role in confirming monitoring reliability:

| Measurable Parameters | Description | Monitoring Data Supporting Reliability |

|---|---|---|

| Frequency | How often odour events occur | Correlation between e-nose readings and human panel assessments |

| Intensity | Strength of odour perceived | Consistent e-nose response patterns matching human perception |

| Duration | Length of odour events | Time-series data from continuous e-nose monitoring |

| Offensiveness | Degree of unpleasantness | Comparison of sensor data with subjective human annoyance reports |

| Impact on receptor | Effect on affected population | Spatial correlation of e-nose data with receptor locations and complaints |

Operators also benefit from integrating citizen alerts, meteorological data, and chemical analysis. These combined approaches ensure systematic management of odour complaints and support compliance with environmental standards.

Community Engagement and Communication

Strong community relations depend on transparent communication and active engagement. Operators who localise messages and connect environmental issues to community values, such as clean air and local pride, foster trust. Effective strategies include:

- Using infographics to explain plant operations and odour control measures.

- Appealing to shared community goals and social norms.

- Combining communication with visible management actions and incentives.

Strategic, localised engagement motivates collective responsibility and supports long-term environmental improvements. Plants that prioritise open dialogue and community involvement often experience fewer complaints and stronger public support.

Common Mistakes and Troubleshooting

Overlooking Equipment Maintenance

Many fish meal plants experience persistent odour issues due to neglected equipment maintenance. Operators who fail to implement regular servicing often see increased emissions. Preventive maintenance routines, carried out by trained personnel, play a crucial role in odour control. Key practices include:

- Frequent cleaning and inspection of all equipment and plant structures

- Keeping spare parts available for immediate repairs

- Replacing worn components before failure to prevent leaks through faulty seals or corroded ducting

- Daily cleaning of drainage areas and collecting tanks

- Maintaining vehicles and containers in good condition

- Systematic recording of instrument readings and observations related to odour

Tip: Consistent preventive maintenance and good housekeeping reduce the risk of unexpected odour releases and support compliance with environmental standards.

Inadequate Process Control

Poor process control remains a leading cause of odour problems in fish meal operations. Incomplete cooking or the use of putrefied feedstocks increases malodorous emissions, especially during drying. Cooker streams release highly odorous compounds when animal matter decomposes under heat. Emission rates of odorous contaminants often rise with higher moisture evaporation and improper temperature settings. Delays in processing raw materials beyond 24 hours or improper handling in storage areas also contribute to odour. Specific units, such as processing tanks and driers, become significant sources if operators do not maintain strict control. Some organic compounds formed during breakdown are detectable at extremely low concentrations, making precise process management essential.

Delayed Response to Odour Complaints

A slow response to odour complaints can damage a plant’s reputation and strain community relations. Operators should establish clear protocols for investigating and addressing complaints promptly. Immediate action demonstrates commitment to environmental responsibility and helps maintain trust with local residents. Regular communication and transparent reporting further support positive engagement and long-term operational success.

Operators achieve the best odour control by combining rapid raw material processing, advanced waste vapour treatment, and strict process monitoring.

- Staff training and regular equipment maintenance remain essential.

- Community engagement builds trust.

Immediate investment in efficient odour solutions protects air quality and strengthens a plant’s reputation.

FAQ

What is the most effective way to reduce odours in fish meal plants?

Operators achieve the best results by combining rapid raw material processing, advanced waste vapour treatment, and strict process monitoring.

How often should equipment maintenance occur for odour control?

Regular maintenance should take place weekly. Operators must inspect, clean, and repair all odour control systems to ensure peak performance.

Why is community engagement important in odour management?

Community engagement builds trust. Operators who communicate openly with residents reduce complaints and support positive relationships.

Post time: Jun-19-2025