Good quality Twin Screw Press - Grinding Machine (China Factory Good Quality Fishmeal Grinding Machine) – Fanxiang

Good quality Twin Screw Press - Grinding Machine (China Factory Good Quality Fishmeal Grinding Machine) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power (kw) |

||

|

L |

W |

H |

||

|

HDSF56*40 |

1545 |

900 |

2100 |

30 |

|

HDSF56*50 |

1650 |

900 |

2100 |

30 |

|

HDSF56*60 |

1754 |

900 |

2100 |

37 |

|

HDSF56*60 (Enhanced) |

1754 |

900 |

2100 |

45 |

working principle

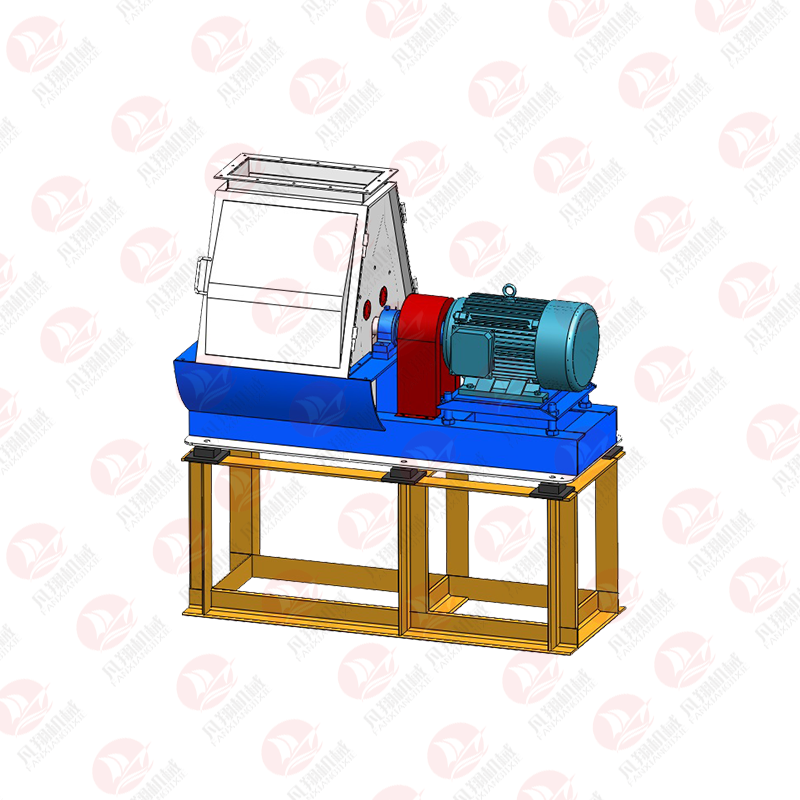

After the processing of the Sieve Screening, fishmeal with some impurities removed still has uneven particles, especially some large shaped fish spines, fish bones, etc., which will affect the processing and quality of the feed, the purpose of crushing all the fishmeal is to facilitate its even mixing in the feed. The crushed fishmeal has an ideal appearance and suitable particle size. Due to the difference in the range of feed applications, different users have different requirements for the particle size of fish meal. Most use specifications that require passing through a 10 mesh sieve hole, otherwise the fish meal would be too coarse to mix evenly. The grinders currently used in the fishmeal industry are basically hammer crusher series, although they vary in dimensions. What we provide is a “water drop shaped crushing chamber hammer crusher”, which has the characteristics of high crushing efficiency, low energy consumption, reasonable structure design, simple maintenance and so on.

When the Grinding Machine works, the fish meal enters the crushing chamber formed by the screen plate from the top of the feed port, and is crushed by the blow action of the high-speed rotary hammer. During this period, the finer particles from the mesh plate sieve leakage, remaining on the screen surface of the larger particles are again hit and repeated crushing, until leakage from the sieve. All the crushed fish meal falls through the outlet to the screw conveyor installed at the discharge port of the Grinding Machine.

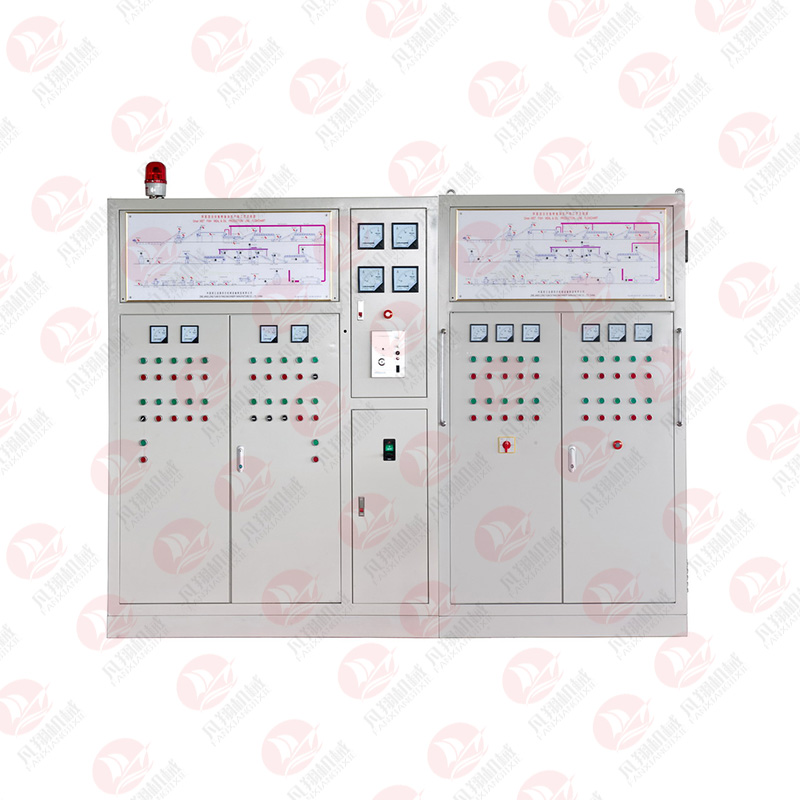

Installation collection

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for Good quality Twin Screw Press - Grinding Machine (China Factory Good Quality Fishmeal Grinding Machine) – Fanxiang , The product will supply to all over the world, such as: Iraq, Nepal, UK, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.