Factory wholesale Fishmeal Machine For Fish Meal Plant - Ion Photocatalytic Purifier (Top Quality Fishmeal Ion Photocatalytic Purifier Production Line Deodorizing System) – Fanxiang

Factory wholesale Fishmeal Machine For Fish Meal Plant - Ion Photocatalytic Purifier (Top Quality Fishmeal Ion Photocatalytic Purifier Production Line Deodorizing System) – Fanxiang Detail:

working principle

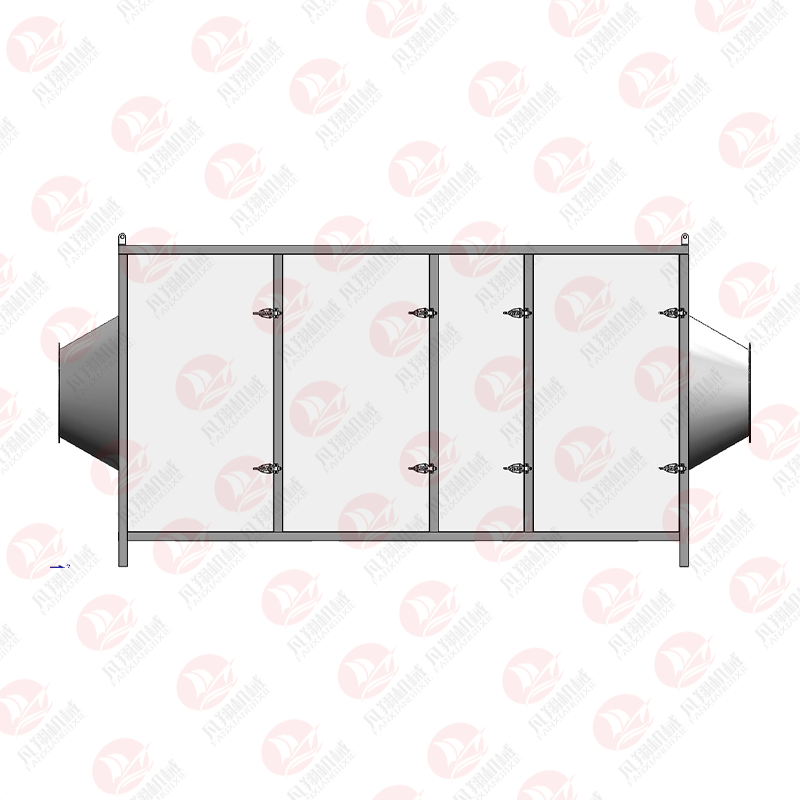

Due to the particularity of fishmeal production industry, deodorization is always an essential part in the production process of fishmeal. In recent years, the relevant domestic and international laws and regulations for the environmental requirements of industrial production are getting higher and higher, making the waste vapor deodorization is receiving more and more attention. Aim to this problem, we developed a new deodorizing equipment focusing on fishmeal industry – Ion Photocatalytic Purifier through repeated experiments and improvements based on and using the most advanced international UV photocatalytic technology and high-energy ion deodorizing technology.

This equipment can effectively decompose waste vapor containing irritating odor substances produced during the fishmeal production, into colorless and odorless water and CO2, so as to achieve the purpose of deodorization and purification of waste vapor, and this equipment has the advantages of high deodorization efficiency, low maintenance costs and stable performance compared with traditional deodorization methods. It is mainly used for the final treatment of fish meal waste vapor. The waste vapor enters the equipment under the action of the Blower after passing through the Deodorizing Tower and Dehumidifier Filter, and is finally discharged into the atmosphere after deodorization by this equipment.

Its working principle is: the high-energy ultraviolet light beam in the process of irradiation to generate a large number of free electrons in the air. Most of these electrons are obtained by oxygen, forming the negative oxygen ions (O3-) which is unstable, and easy to lose an electron and become active oxygen (ozone). Ozone is advanced antioxidant that can oxidative decomposition of organic and inorganic substances. The main odorous gases such as hydrogen sulfide and ammonia can react with ozone. Under the action of ozone, these odorous gases are decomposed into small molecules from big molecules until mineralization. After the ion photocatalytic purifier, the waste vapor can be directly discharged into the air.

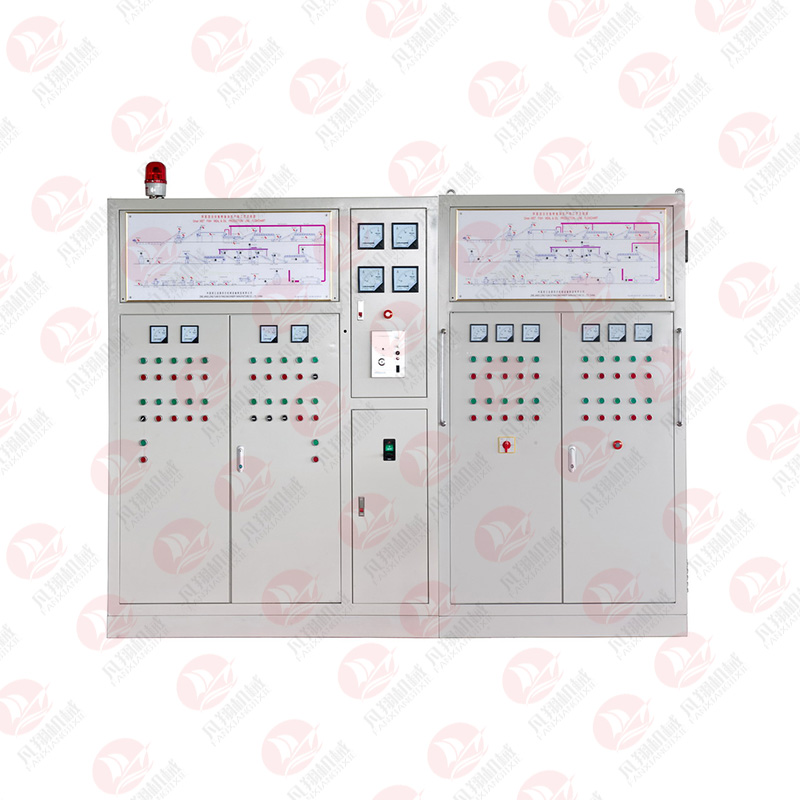

Installation collection

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory wholesale Fishmeal Machine For Fish Meal Plant - Ion Photocatalytic Purifier (Top Quality Fishmeal Ion Photocatalytic Purifier Production Line Deodorizing System) – Fanxiang , The product will supply to all over the world, such as: Thailand, United States, Washington, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!