Factory Free sample Centrifuge Separator With Tricanter - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang

Factory Free sample Centrifuge Separator With Tricanter - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power(kw) |

||

|

L |

W |

H |

||

|

SJRQ-Ø219*3000 |

3000 |

380 |

640 |

0.25 |

|

SJRQ-Ø219*4000 |

4000 |

380 |

640 |

0.25 |

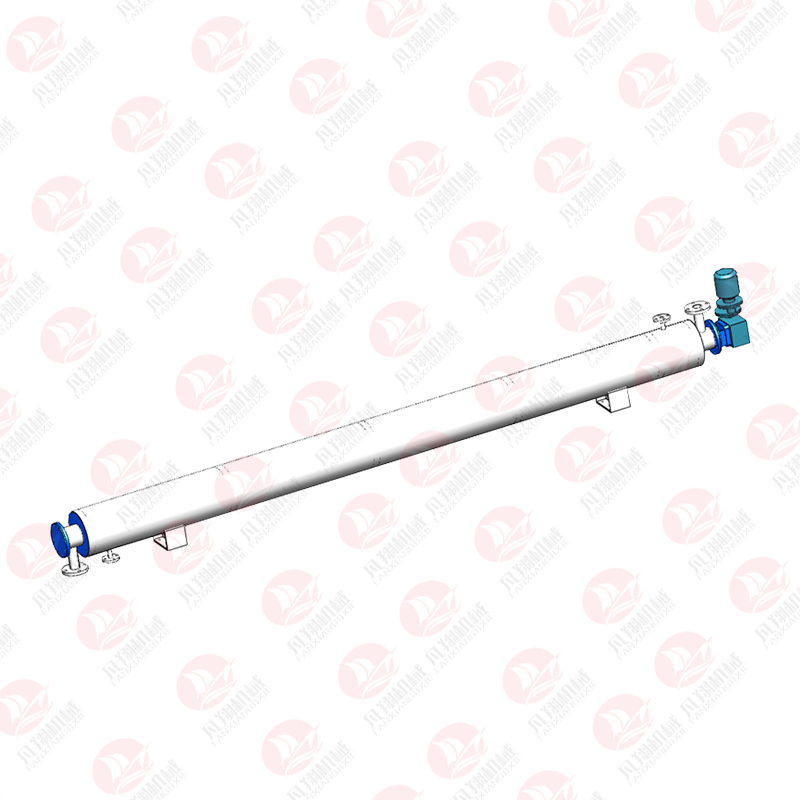

working principle

The protein water extruded from the Screw Press must be preheated before entering the Tricanter, and the temperature can be controlled at 90℃~95℃, which is conducive to the separation of oil and water. The working principle of Protein Water Heater is to heat protein water by indirect heat exchange between steam and protein water. The steam enters the shell insulation cover from the steam inlet of the power end, and the protein water enters the main shaft of Protein Water Heater from the non-power end. After indirect heat exchange between steam and protein water, the condensate water generated in the heat exchange process is discharged from the condensate outlet at the bottom of the non-power end, and the heated protein water is discharged from the outlet at the power end and then fed into the Tricanter for centrifugal separation. Steam and protein water enter the Protein Water Heater from opposite directions in order to achieve better heating effect, so that the temperature of the protein water discharged from the outlet is the highest.

Structure

|

No. |

Description |

No. |

Description |

|

1. |

Protein water inlet flange |

5. |

Spindle joint |

|

2. |

Condensed water outlet flange |

6. |

Steam inlet flange |

|

3. |

Foot stand |

7. |

Protein water outlet flange |

|

4. |

Barrel-body parts |

8. |

Insulation cover |

Installation collection

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high-quality handle, reasonable rate, superior services and close co-operation with prospects, we are devoted to furnishing the best price for our customers for Factory Free sample Centrifuge Separator With Tricanter - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang , The product will supply to all over the world, such as: St. Petersburg, Norwegian, Provence, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.