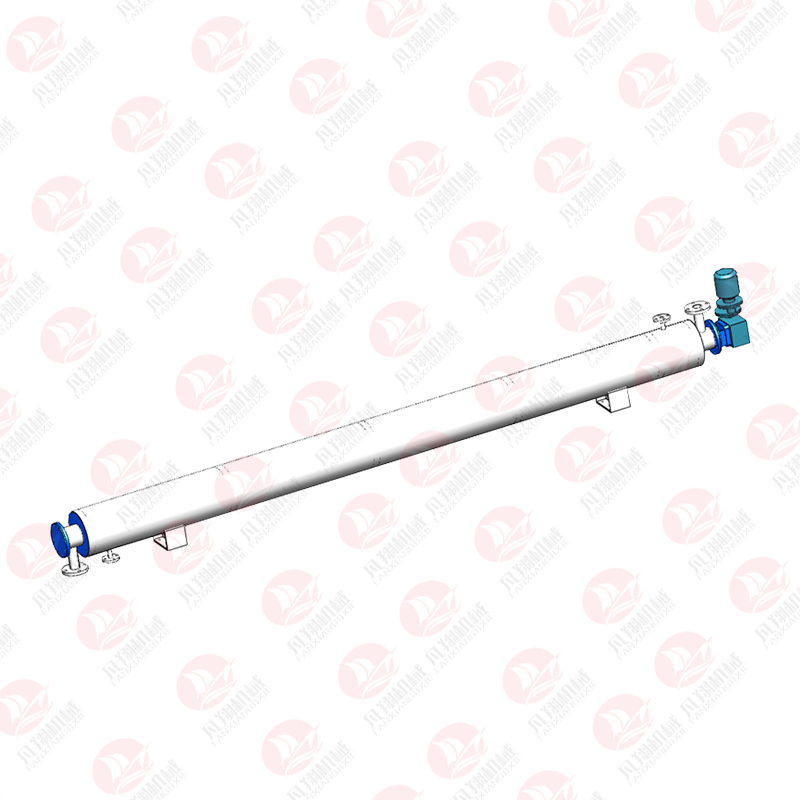

China Cheap price Fish Oil Filter System - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang

China Cheap price Fish Oil Filter System - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power(kw) |

||

|

L |

W |

H |

||

|

SJRQ-Ø219*3000 |

3000 |

380 |

640 |

0.25 |

|

SJRQ-Ø219*4000 |

4000 |

380 |

640 |

0.25 |

working principle

The protein water extruded from the Screw Press must be preheated before entering the Tricanter, and the temperature can be controlled at 90℃~95℃, which is conducive to the separation of oil and water. The working principle of Protein Water Heater is to heat protein water by indirect heat exchange between steam and protein water. The steam enters the shell insulation cover from the steam inlet of the power end, and the protein water enters the main shaft of Protein Water Heater from the non-power end. After indirect heat exchange between steam and protein water, the condensate water generated in the heat exchange process is discharged from the condensate outlet at the bottom of the non-power end, and the heated protein water is discharged from the outlet at the power end and then fed into the Tricanter for centrifugal separation. Steam and protein water enter the Protein Water Heater from opposite directions in order to achieve better heating effect, so that the temperature of the protein water discharged from the outlet is the highest.

Structure

|

No. |

Description |

No. |

Description |

|

1. |

Protein water inlet flange |

5. |

Spindle joint |

|

2. |

Condensed water outlet flange |

6. |

Steam inlet flange |

|

3. |

Foot stand |

7. |

Protein water outlet flange |

|

4. |

Barrel-body parts |

8. |

Insulation cover |

Installation collection

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for China Cheap price Fish Oil Filter System - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang , The product will supply to all over the world, such as: Casablanca, Barcelona, Mexico, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.