Cheap PriceList for Drum Fish Oil Centrifuge Separator Machine - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang

Cheap PriceList for Drum Fish Oil Centrifuge Separator Machine - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang Detail:

|

Model |

Dimensions(mm) |

Power(kw) |

||

|

L |

W |

H |

||

|

SJRQ-Ø219*3000 |

3000 |

380 |

640 |

0.25 |

|

SJRQ-Ø219*4000 |

4000 |

380 |

640 |

0.25 |

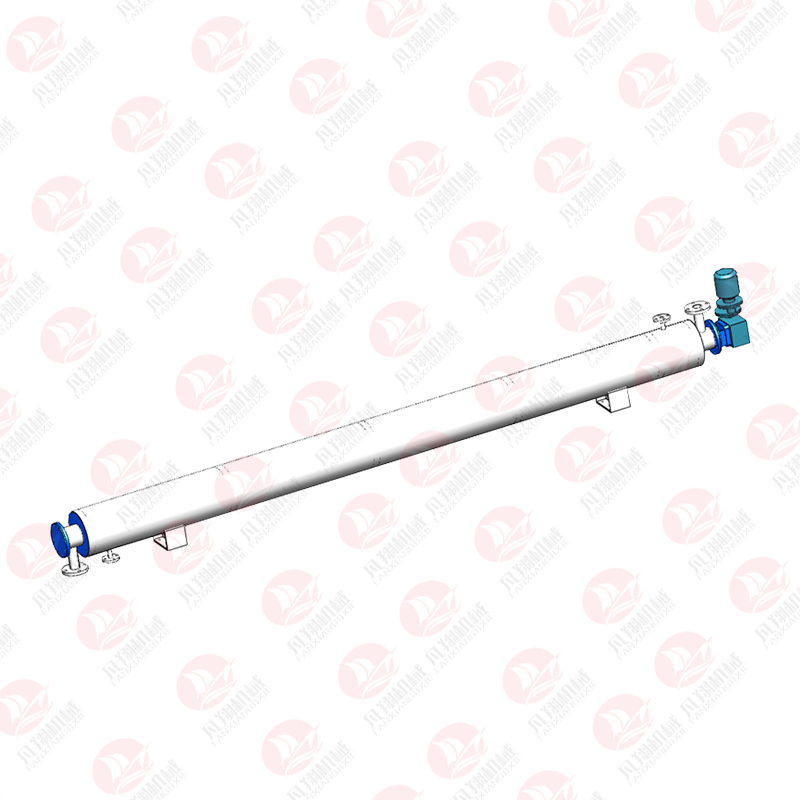

working principle

The protein water extruded from the Screw Press must be preheated before entering the Tricanter, and the temperature can be controlled at 90℃~95℃, which is conducive to the separation of oil and water. The working principle of Protein Water Heater is to heat protein water by indirect heat exchange between steam and protein water. The steam enters the shell insulation cover from the steam inlet of the power end, and the protein water enters the main shaft of Protein Water Heater from the non-power end. After indirect heat exchange between steam and protein water, the condensate water generated in the heat exchange process is discharged from the condensate outlet at the bottom of the non-power end, and the heated protein water is discharged from the outlet at the power end and then fed into the Tricanter for centrifugal separation. Steam and protein water enter the Protein Water Heater from opposite directions in order to achieve better heating effect, so that the temperature of the protein water discharged from the outlet is the highest.

Structure

|

No. |

Description |

No. |

Description |

|

1. |

Protein water inlet flange |

5. |

Spindle joint |

|

2. |

Condensed water outlet flange |

6. |

Steam inlet flange |

|

3. |

Foot stand |

7. |

Protein water outlet flange |

|

4. |

Barrel-body parts |

8. |

Insulation cover |

Installation collection

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Cheap PriceList for Drum Fish Oil Centrifuge Separator Machine - Protein Water Heater (Good Quality Fish Meal And Oil Processing Protein Water Heater Machine And Equipment) – Fanxiang , The product will supply to all over the world, such as: British, Mauritius, Gambia, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.