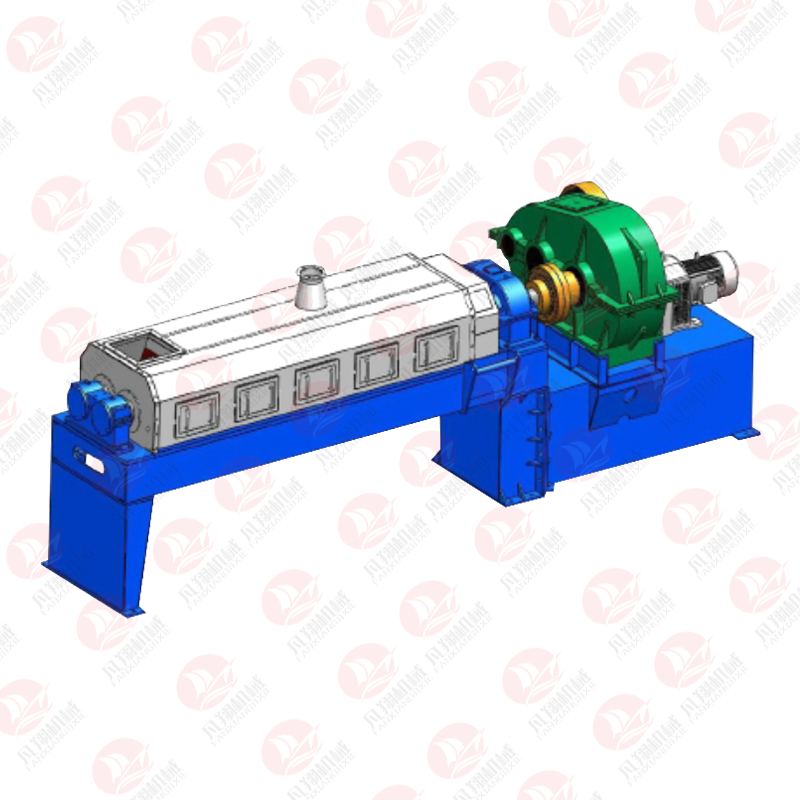

2021 New Style Belt Conveyor Packaging System - Screw Press (High Quality Double Screw Press Fishmeal Processing Machine) – Fanxiang

2021 New Style Belt Conveyor Packaging System - Screw Press (High Quality Double Screw Press Fishmeal Processing Machine) – Fanxiang Detail:

|

Model |

Capacity (t/h) |

Dimensions(mm) |

Power (kw) |

||

|

L |

W |

H |

|||

|

SY-50T |

﹥2.1 |

5500 |

1400 |

1770 |

15 |

|

SY-80T |

﹥3.4 |

5550 |

1500 |

1775 |

15 |

|

SY-100T |

﹥4.2 |

5620 |

1500 |

1775 |

18.5 |

|

SY-150T |

﹥6.3 |

6100 |

1665 |

1880 |

22 |

|

SY-200T |

﹥8.4 |

6440 |

1665 |

1880 |

22 |

|

SY-300T |

﹥12.5 |

7700 |

1930 |

2085 |

37 |

|

SY-400T |

﹥16.7 |

8671 |

1780 |

2481 |

55 |

|

SY-500T |

﹥20.8 |

9300 |

1780 |

2481 |

75 |

working principle

The function of the Screw Press is to squeeze out the stick water in the solid phase pressed cake as much as possible, which is not only important to improve the yield of fish oil and the quality of fish meal, but also to reduce the moisture content of the pressed cake as much as possible, so as to reduce the workload of the Drier and improve the production capacity of the equipment.

The cooked material is fed from the feed port, and as the pitch of the twin screws of the press gradually decreases along the discharge end while the diameter gradually increases, the raw material located in the screw grooves of the two shafts is gradually compressed, generating a pressure of up to 15kg/cm2 or more. In this process, due to the interaction of the twin screws, it not only prevents the raw material from rotating with the shaft, but also strengthens the mixing and shearing effect on the raw material, which is conducive to the dehydration and degreasing of the raw material. As the raw material is continuously compressed, the stick water continuously flows out from the sieve hole of the stainless steel mesh plates, collects in the liquid receiver hopper and flows from the outlet into the stainless steel protein water tank; while the pressed cake falls from the outlet and is conveyed by the screw conveyor into the Drier.

Installation collection

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for 2021 New Style Belt Conveyor Packaging System - Screw Press (High Quality Double Screw Press Fishmeal Processing Machine) – Fanxiang , The product will supply to all over the world, such as: Kyrgyzstan, Greece, Qatar, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.