100% Original Factory Steam Heated Cooking Machine - Condensate Recovery Device (High Quality Condensate Recovery Device Steam Condensate System) – Fanxiang

100% Original Factory Steam Heated Cooking Machine - Condensate Recovery Device (High Quality Condensate Recovery Device Steam Condensate System) – Fanxiang Detail:

working principle

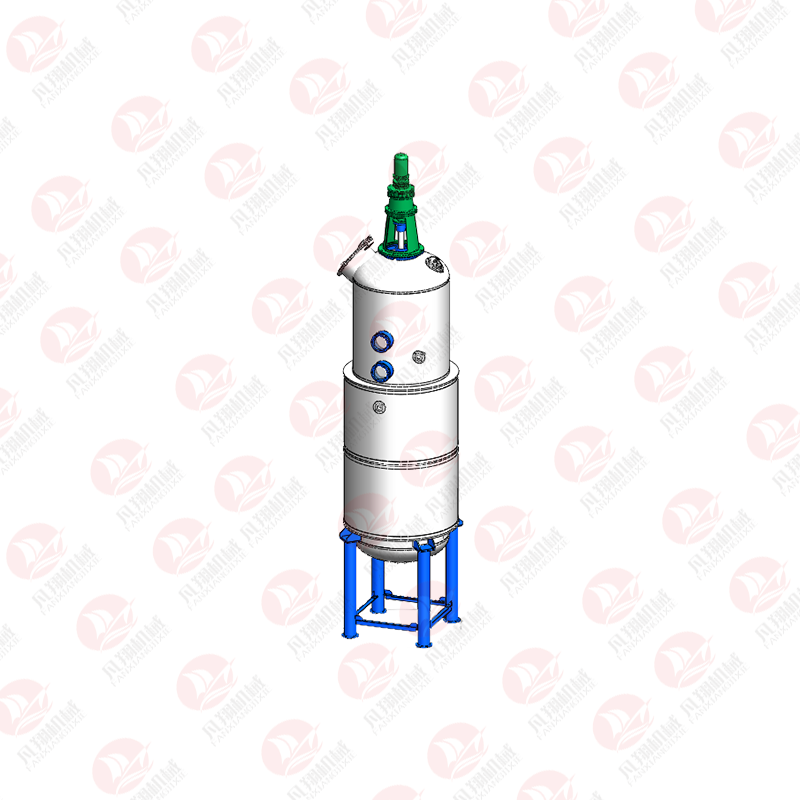

In fishmeal and fish oil production lines, equipment such as Cookers and Driers that use steam for indirect heating will produce a large amount of high temperature steam condensate above 100°C due to the indirect heat exchange in the production process. Recycling this condensate not only saves industrial water, but also saves boiler fuel, reduces air pollution and improves boiler thermal efficiency. But if only supporting a boiler tank and a hot water pump to collect condensate water, the latent heat of the steam condensate will be dissipated before it enters the boiler, thus reducing the recovery value of steam condensate. In response to the above situation, the Condensate Recovery Device developed by our company just solves this problem. The Condensate Recovery Device is mainly composed of a collection tank with pressure, a high temperature multi-stage pump, a magnetic flap level gauge and a pressure reducing valve. The condensate with a small amount of steam is collected through pipes into the relatively closed collection tank, the pressure in the tank can be controlled by using a pressure reducing valve. When the water level in the collection tank reaches a certain height, the high temperature multi-stage pump will be controlled by the magnetic flap level gauge to deliver the condensate and steam to the boiler as make-up water, which increases the actual thermal efficiency of the boiler, and the potential of the boiler is fully realized.

Installation collection

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, usually regards product top quality as business life, repeatedly enhance manufacturing technology, make improvements to product excellent and continuously strengthen enterprise total high quality administration, in strict accordance with all the national standard ISO 9001:2000 for 100% Original Factory Steam Heated Cooking Machine - Condensate Recovery Device (High Quality Condensate Recovery Device Steam Condensate System) – Fanxiang , The product will supply to all over the world, such as: Germany, Marseille, Sri Lanka, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.